Transmission Construction with the 10k & 20k Power Line Dynamometers

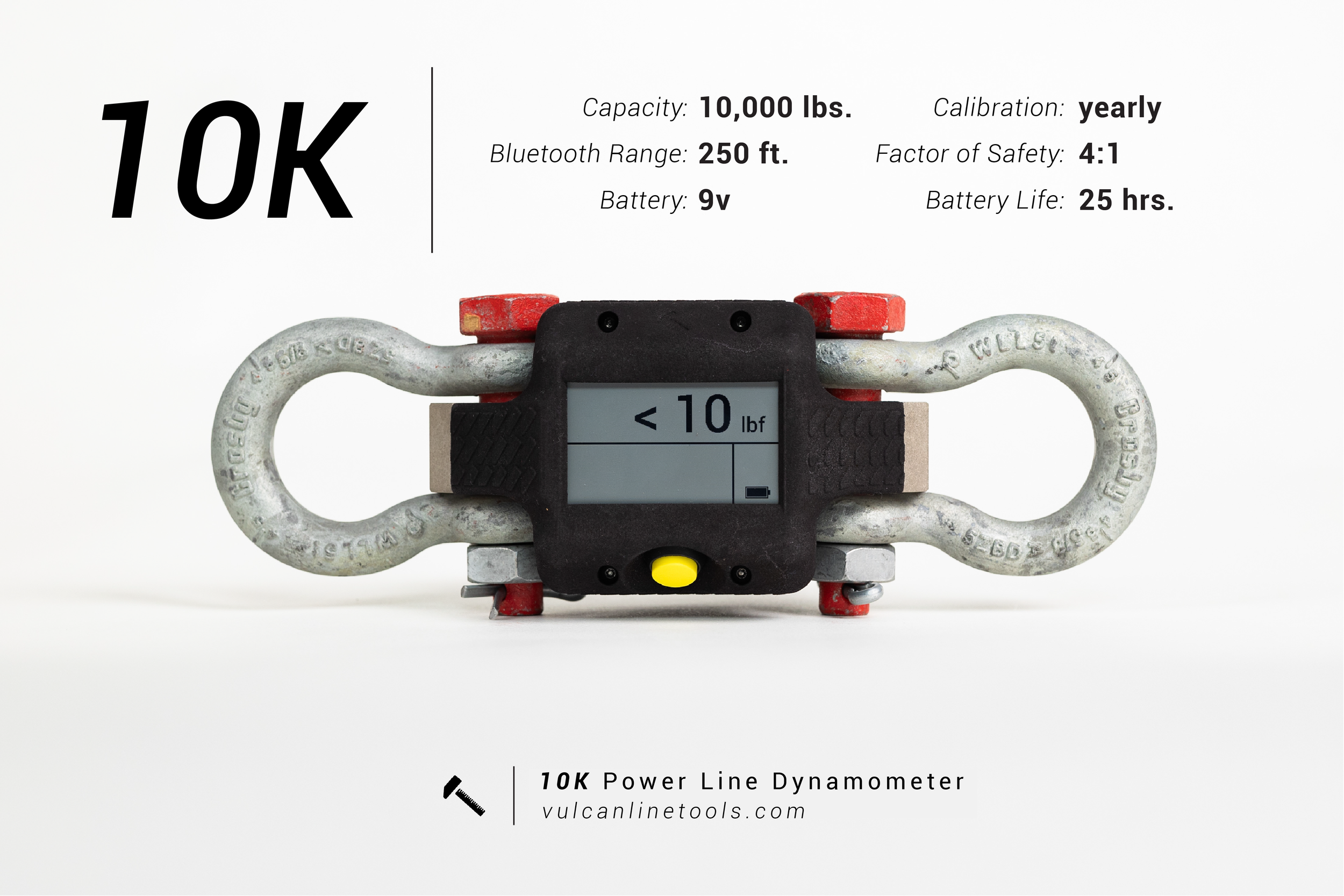

The 10k Power Line Dynamometer by Vulcan Line Tools.

Optimizing Transmission Line Construction: The Critical Role of Power Line Dynamometers

Transmission systems play a crucial role in the electric grid, acting as high voltage superhighways between generation sources and the distribution poles that connect to your home. Ensuring safety and reliability in these systems is critical, and it starts with effective construction. During the transmission construction process, crews must carefully build spans to mirror engineering plans while remaining on-budget and safe. This is no small feat, and it requires planning and efficient execution. There is no room for error in transmission construction, and performing the many stages to complete a reliable build takes time and resources.

One of the final stages of construction is called conductor pulling. In this stage, linemen tension power lines to the exact sag values that they were engineered for. At Vulcan Line Tools, we created the most effective transmission line-tensioning devices on the market: the 10k and 20k Dynamometers. These power line dynamometers are essential instruments in modern transmission projects, setting a new standard of accuracy and efficiency in transmission construction workflows. So how are transmission lines built and what role do power line dynamometers play?

Understanding Electric Power Transmission System Construction

How Are Transmission Lines Built?

Before any conductor ever leaves the spool, transmission line construction begins with careful planning and site preparation. Engineers perform route surveys to identify optimal routes, taking into account terrain, environmental constraints, and regulatory requirements. Once the right-of-way (ROW) is secured and cleared of vegetation or obstacles, crews lay out and excavate for foundations. Concrete footings are poured and allowed to cure, after which tower components are assembled on the ground. Specialized cranes then erect each tower section, bolt by bolt, and precision survey teams verify that every structure meets strict vertical and lateral tolerances before moving on to the next span.

Once tower erection is complete, crews pull transmission lines into place between each tower in an important stage known as conductor stringing. Stringing consists of two steps: pulling and sagging. During conductor pulling, linemen place traveler blocks (grooved pulleys) atop each tower to guide the conductor. At either end of the span, ground-based pulling mechanisms control the conductor’s movement and tension. Crews first run a lightweight pilot line through the blocks, which is then used to pull the transmission conductor back through. Once pulling is complete, linemen can use various methods and tools to sag the wires. This final step is critical, allowing linemen to fine-tune conductor sag and tension before clipping the conductor into place on each structure.

What Role do Power Line Dynamometers Play in Transmission Construction?

During a transmission construction project, linemen can use a dynamometer during conductor stringing and when performing inventory. During pulling, a dynamometer is placed in-line with the conductor to monitor real-time load and prevent overstressing. This is not always common practice but it promotes safety and minimizes re-work. In the sagging phase, the dynamometer is positioned between the conductor and the anchoring hardware, enabling crews to fine-tune tension based on conductor type, span length, and ambient temperature. At the heart of the stringing process is the need for accuracy, and linemen use these tools to ensure transmission lines, and the towers they are attached to, are not at risk of failure from excessive tension or clearance violations.

Some construction crews opt to not use dynamometers during these stringing steps, choosing to pull conductors without watching their real-time load and performing sagging with various other instruments. Though these methods can yield similarly satisfactory results, they involve risk and inefficiencies. Vulcan’s 10k and 20k Dynamometers eliminate such issues, making this process faster, safer, and more consistent than any other method or competing dynamometer out there. Vulcan’s dynos also allow users to take inventory by weighing conductor spools, which is unique to only our tools. To better understand the benefits of our dynos, the following section outlines their technical specifications and unique applications.

What are the 10k and 20k Dynamometers?

An Image of the 10k Dynamometer’s Technical Specifications

Technical Specifications

Built with durable rubber casing, water-resistant internals and anti-glare displays, the 10k and 20k Dynamometers are meant for the wear and tear of years in the field. With capacities of 10,000 lbs and 20,000 lbs respectively, they can handle the toughest jobs. But durability isn’t all that sets them apart from the competition; our dynos contain Bluetooth technology, enabling real-time data transmission to and from the Vulcan Line Tools app on mobile devices. With Bluetooth ranges of up to 250 ft, users can load utility sag charts directly into the device to calculate required tension based on conductor type, ruling span and pulling conditions. Once the desired tension is met, users can export the measurement to a mobile device as a detailed PDF report.

An Image of the 20k Dynamometer’s Technical Specifications

Unique Applications

Vulcan dynamometers can also assist linemen with inventory. Using the linear feet calculator on the Vulcan Line Tools app, you can estimate remaining conductor footage on a conductor spool. Users must simply enter the empty spool weight and conductor type into the app, attach the dyno to a conductor spool and lift it with a crane, forklift, etc. Both the dynamometer and the app will read the remaining linear feet remaining in the reel. The measurement can be exported as a pdf report.

What are the Advantages of the VLT 10k and 20k Dynamometers Over Traditional Methods?

Unique applications aside, there are a few primary advantages to the Vulcan dynamometers in comparison to traditional methods. These advantages—which stem from the tools’ sleek designs and Bluetooth technology— include enhanced accuracy, streamlined data management, and significant time-saving during transmission builds. Traditional transmission construction projects require linemen to compare paper sag charts to their dynos while in the bucket or via radio with a foreman on the ground. With a Vulcan dyno, users can simply load in their sag charts and let the Vulcan App calculate a span’s necessary tension. This tension value will then display on both the app and the dynamometer’s screen, removing the possibility of user error and improving workflows.

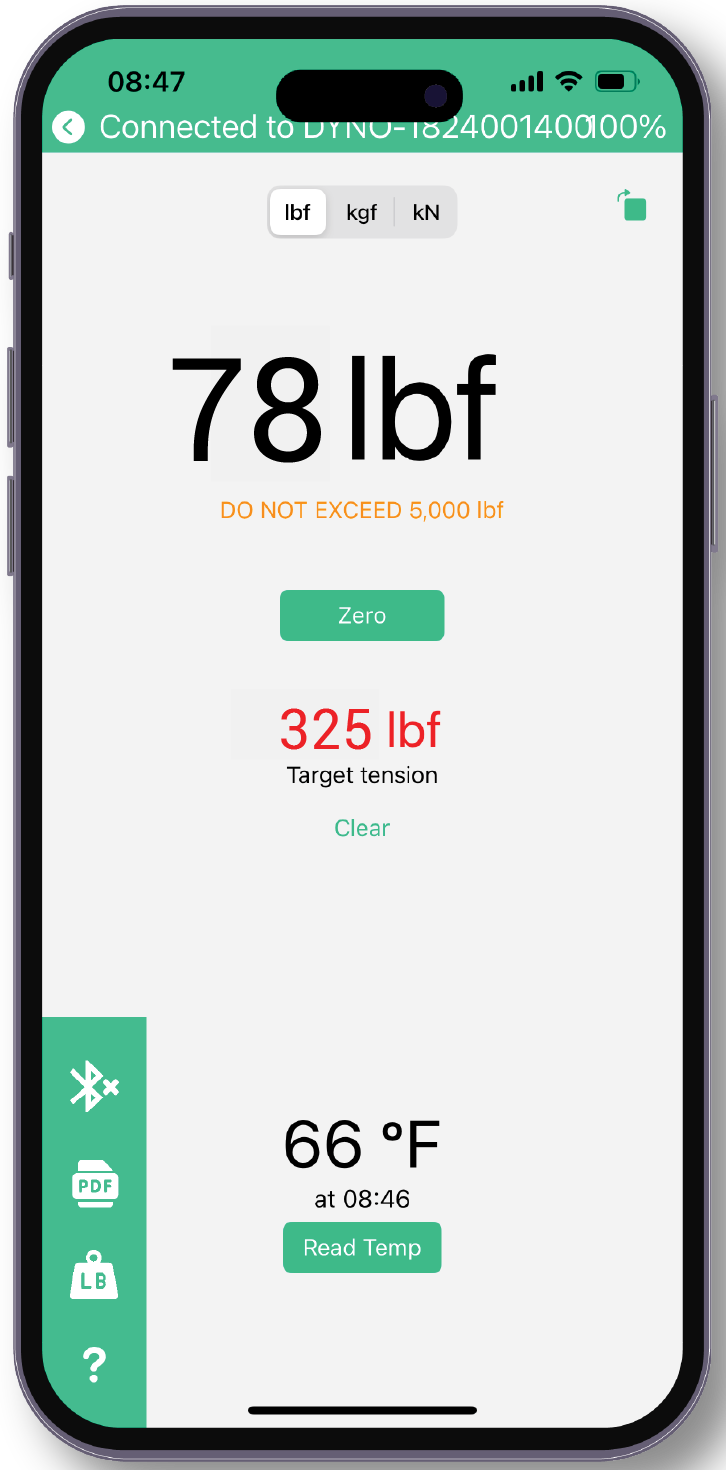

A dynamometer’s live tension measurement is displayed on the Vulcan Line Tools App

As a result, measurements become faster and more accurate, improving construction speeds and eliminating rework. Without sag chart integrated dynos or when pulling without measuring, linemen are typically not able to match conductor tension to their target tension. This means that crews will perform extensive sagging on the back end in order to bridge the gap between their pulling tensions and their targets. With a Vulcan dyno, accuracy in the initial stage of stringing is quite good, meaning the sagging process will require minimal rework because the initial pulling tensions were measured with quality.

The most prevalent sagging method involves the use of a scope with crosshairs to visually match the low point in a conductor to a predetermined minimum clearance height. Crews must again account for various factors like conductor type, span length and ambient temperature in order to set their crosshairs at the most optimal height. These factors, which are all contained in utility sag charts, can be accounted for properly when loaded into the Vulcan dynamometers. Linemen can be especially confident in their sagging measurements when pairing a Vulcan dyno with the WaveTimer, which we built specifically for measuring conductor sag. Regardless of how you use our dynamometers, their capacity to improve transmission builds and grid reliability more generally is next to none.

Conclusion: Elevating Transmission Construction Standards

The long-term success of modern transmission systems hinges on precise control of conductor tension, and Vulcan Line Tools’ 10k and 20k Dynamometers bring that precision into construction workflows. By integrating durable, field-ready hardware with Bluetooth-enabled sag chart calculations and real-time data export via the Vulcan app, these dynamometers streamline conductor pulling, sagging, and inventory management into a single, error-proof workflow. The result is faster stringing, fewer rework cycles, and fully documented tension reports that enhance both safety and efficiency on the grid. Whether monitoring pull forces, fine-tuning sag in challenging conditions, or estimating remaining footage on a spool, Vulcan’s dynos set a new standard for accuracy and productivity in transmission projects, helping utilities construct more reliable, resilient power networks.

Ready to take your transmission projects to the next level?

For more detailed information, visit our Dynamometers page or learn more from our informational Youtube videos.

You can also download our detailed product brochure to see how our Dynamometers can help you achieve unmatched accuracy and efficiency in the field.

If you want to get in touch with us, click the button below!